Square stack lining material

TOMBO™ No. 6496

CERASTUCK™

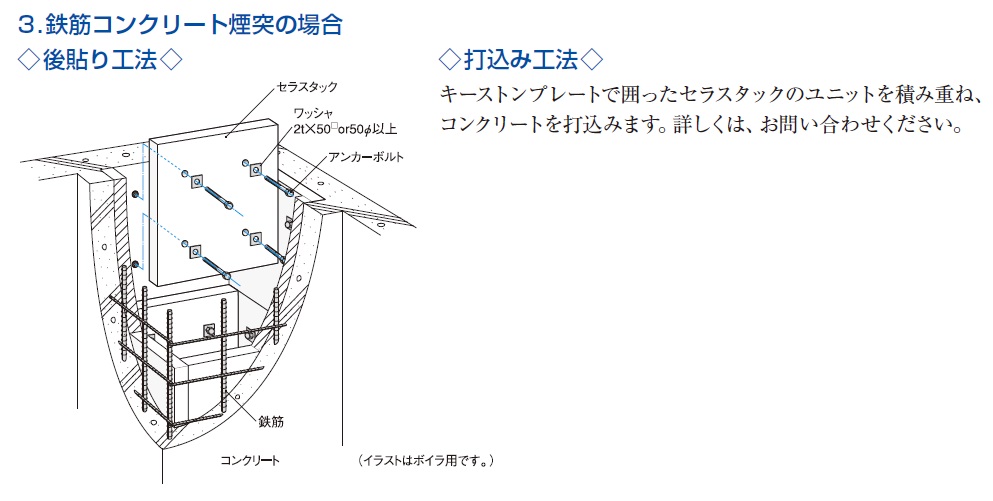

CERASTUCK is a board-shaped stack lining material with excellent heat resistance and workability. It is made by adding aggregate and inorganic reinforced fibers to its main material Xonolite (calcium silicate). It can be used for the exhaust of boilers for distributing hot water and heating as well as the exhaust of internal combustion engines of home power-generation facilities.

Product Category

Building Materials(For Residential Housing/Non-Residential)Stack Lining Materials

Industry

Residential Housing & Non-ResidentialBuilding (Non-Residential) ConstructionBuilding FacilitiesVarious Plant FacilitiesBoilers

Forte

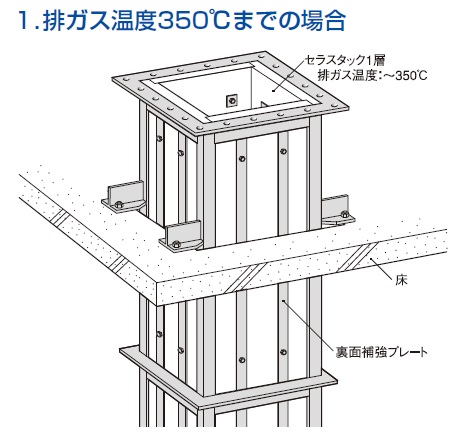

There are three product thicknesses: 35 mm, 50 mm, and 70 mm. By combining these, it is possible to set an efficient thermal insulation material thickness according to the temperature of exhaust gas.

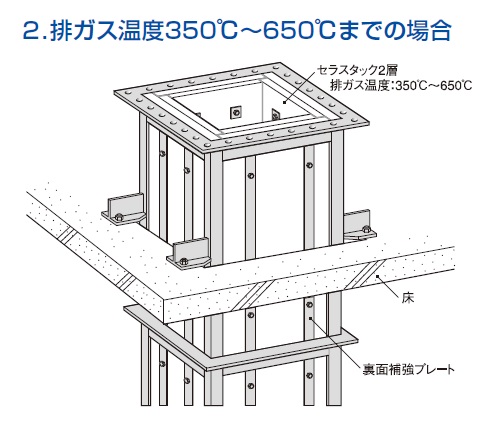

Its two-layer structure can support high-temperature exhaust gas. (Made for use with power generators and cogeneration systems)

A two-layer structure is used to mitigate the impact of heat if the temperature of exhaust gas is between 350°C to 650°C, and this improves the safety of smokestacks.

*If the temperature of exhaust gas is 350°C or less, a single board with a thickness of 50 mm or 70 mm can be used.

Specification

When using CERASTUCK in any construction method, make sure to install a cowl cover.

Standard performance

| Safe working temperature (°C) | Upper limit | 650 |

|---|---|---|

| Lower limit | Depends on the type of fuelNote 1 | |

| Density (kg/m3) | 500±50 | |

| Bending strength (N/mm2) | 2.94 or more | |

| Heat shrinkage rate (%) 650°C×3h |

Length direction | 0.35 or less |

| Thermal conductivity (W/(m・K)) | 0.079 + 0.000049 θ Note 2 | |

Note 2: These values are our actual measurement values. They are not standard values.

Standard dimensions

| Thickness (mm) | Width (mm) | Length (mm) | Weight (kg/piece) |

|---|---|---|---|

| 35 | 1, 250 | 2, 500 | 55 |

| 50 | 78 | ||

| 70 | 109 |

Exhaust gas temperature upper limit & lower limit

Single layer = 350°C or less

Double layer = 650°C or less

Exhaust gas temperature lower limit (smokestack outlet)

Please adhere to the table below according to the type of fuel.

[Exhaust Gas Temperature Lower Limit of Smokestack Outlet by Fuel Type]

| Fuel type | Smokestack outlet Exhaust gas temperature lower limit |

Reason |

|---|---|---|

| Fuel oil A | 160°C or more | To prevent degradation of the lining material from the sulfuric acid condensation of SO3 within the exhaust gas. |

| Fuel oil B | 180°C or more | |

| Kerosene | 130°C or more | |

| LP gas | 130°C or more | |

| Diesel oil | 120°C or more | |

| City gas 13 A, 12 A, 6A, etc. |

120°C or more | To prevent degradation of the lining material from excessive water (dew condensation) absorption. |

*If the exhaust gas temperature will go below the aforementioned lower limit during the operating of equipment, make sure to cover all surfaces inside the smokestacks with SUS plates (stainless steel plates).

*If you do not know the exhaust gas temperature lower limit, cover all surfaces inside the smokestacks with SUS plates.

Other

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.