| Types of lining material | ||

|---|---|---|

| PFA | FA/ PFA |

PFA is a fluororesin that can be melted and molded. It is similar to PTFE in that it has resistance against almost all pharmaceuticals, but compared to PTFE, it has excellent strength at high temperatures and compressive creep resistance. It is widely used for tanks at chemical plants, oil plants, pharmaceutical manufacturing plants, and semiconductor plants. There are two types: “FA”, with brown pigment added for chemical plants and general industries, and “PFA”, a colorless material for high-purity chemicals that are adverse to eluted metals. |

| PFA-HG | A PFA uses New-PFA with little fluorine ion elusion for semiconductor applications as its raw material and has a smooth surface. Its smooth surface means it can be cleaned more quickly. As PFA-HG has about half the gas permeation of PFA, it reduces the contamination of high-purity liquid medicines from environmental stress cracks (nozzles and welded parts), reductions in adhesive strength, and reverse osmosis during long-term use. PFA-HG is suitable for use in tanks for semiconductor production that has strict cleanliness requirements. | |

| PTFE | PTFE is welded with PFA because it cannot be used for welding and molding due to its high melt viscosity and it cannot be welded with the same material. | |

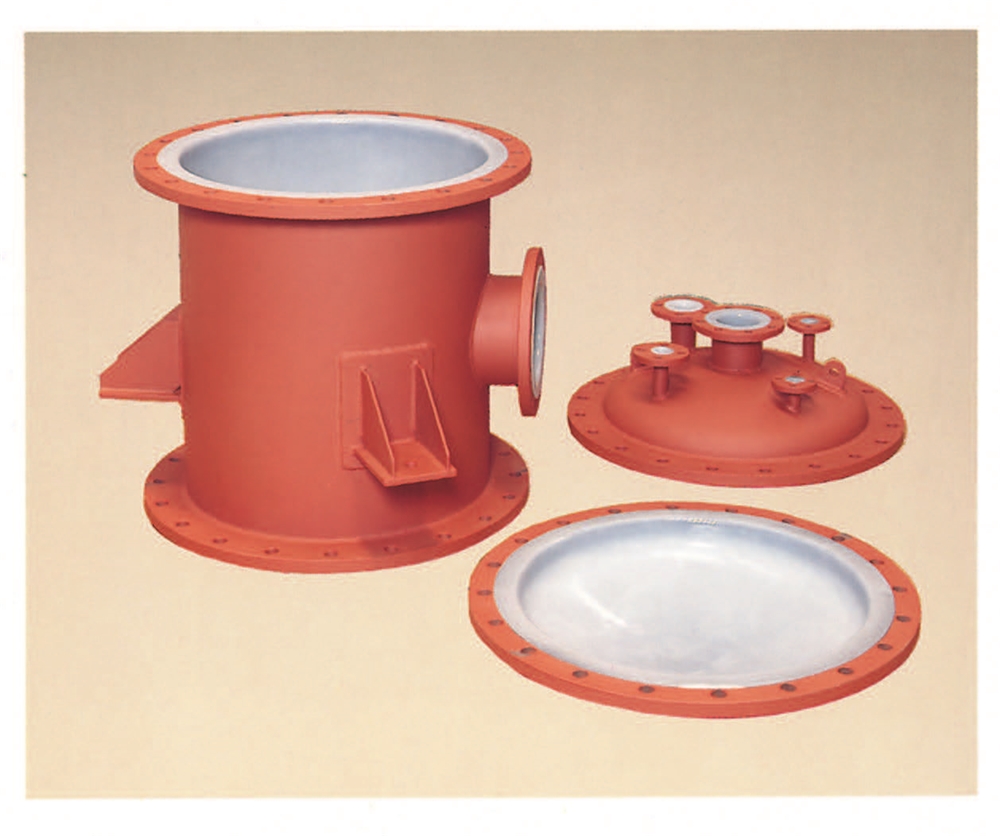

Fluoropolymer tank lining

Fluoropolymer tank lining

As an application that utilizes the excellent chemical resistance and heat resistance of fluororesin, it is used as a corrosion-resistant lining for large-diameter tanks, stress tanks, and towers. Nichias offers PFA and PTFE fluororesins as types of lining materials, and thanks to Nichias’ various lining methods, the materials have a broad temperature range and chemical resistance, as well as excellent performance in a wide pressure range.

Product Category

Fluororesin ProductsCorrosion-Resistant Linings

Industry

Chemistry & PetrochemistryOil Refining & PetrochemistryChemistry

Lining material and installation method

Properties according to the lining installation method

| Properties according to the lining installation method | Types of lining material | PFA | PTFE | ||||||

|---|---|---|---|---|---|---|---|---|---|

| FA/PFA PFA-HG |

FA/PFA PFA-HG |

PFA | PTFE | ||||||

| Lining method | LooseNote 2 | AdhesionNote 2 | Coatings | AdhesionNote 2 | |||||

| Sheet lining material | - | Glass cloth or Carbon-based cloth |

- | (chemical etching) | |||||

| Types of adhesive | - | Rubber-based or Epoxy-based |

- | Rubber-based or Epoxy-based |

|||||

| Maximum working temperature | 150°C | 150°C | 100°C | 60°C | |||||

| Chemical resistance | Acid resistance | Excellent | Excellent | ExcellentNote 1 | Excellent | ||||

| Alkali resistance | Excellent | Excellent | Excellent | Excellent | |||||

| Solvent resistance | Excellent | Excellent | Excellent | Excellent | |||||

| Installation to a panel board and integrated tank | Not possible | Possible | Possible | Possible | |||||

Note 2: When using PFA and PTFE sheet lining at a vacuum pressure, the sheet may deform or peel. If using at a vacuum pressure, you must adopt a vacuum balance approach that aspirates from the outside of the sheet.

*This product may fall under controlled goods defined by “Foreign Exchange and Foreign Trade Act”. If so, export admission according to the act above is required for exporting such a product.

Other

- TOMBO is a registered trademark or trademark of NICHIAS Corporation.

- Name of products with "®" are registered trademarks of NICHIAS Corporation.

- Name of products with "™" are trademarks of NICHIAS Corporation.