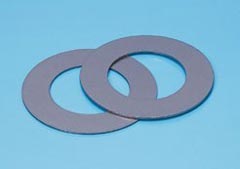

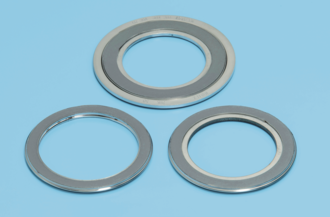

Expanded graphite gasket

GRASEAL™ GASKET

TOMBO™ No. 1200

It is more cost-effective than the other GRASEAL GASKET models.

As it is weaker and less workable than the steel sheet type, Nichias recommends using it only for nominal diameters of 4 inches or less.

It can be used for uniquely shaped flanges such as liquid level gauges, as well as various industrial pipe flanges, heat exchanges, and valve bonnets.

Expanded graphite gasket

GRASEAL™ GASKET MI-A

TOMBO™ No. 1210-A

It is stronger than TOMBO No.1215-A due to its pronged steel plate.

Nichias recommends this product if TOMBO No.1215-A is not strong enough for you or if there are specification restrictions.

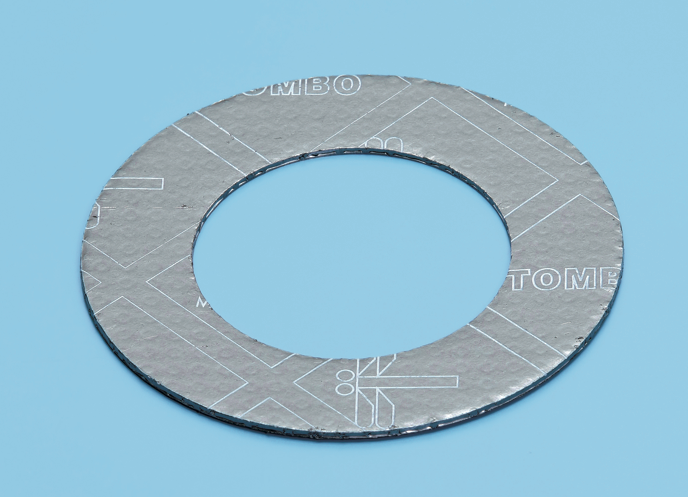

Expanded graphite gasket

GRASEAL™ GASKET PM

TOMBO™ No. 1215

It has excellent workability and can be machined into complex shapes.

It is used for uniquely shaped flanges, valve bonnets, heat exchangers, etc.

Nichias also offers TOMBO No.1215-T, which has improved sealing performance against gas by undergoing treatment to make it impervious. (However, its maximum working temperature is 260°C.)

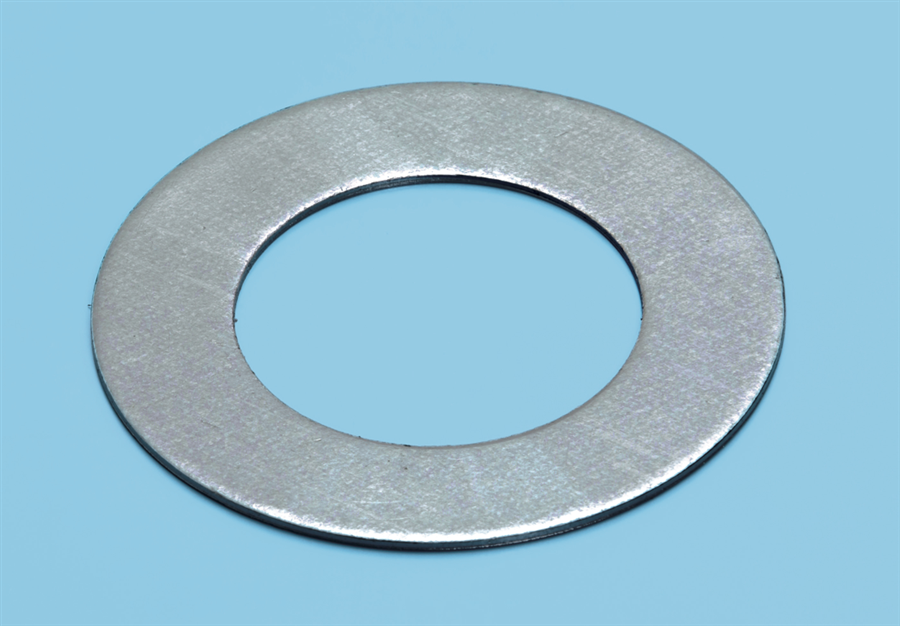

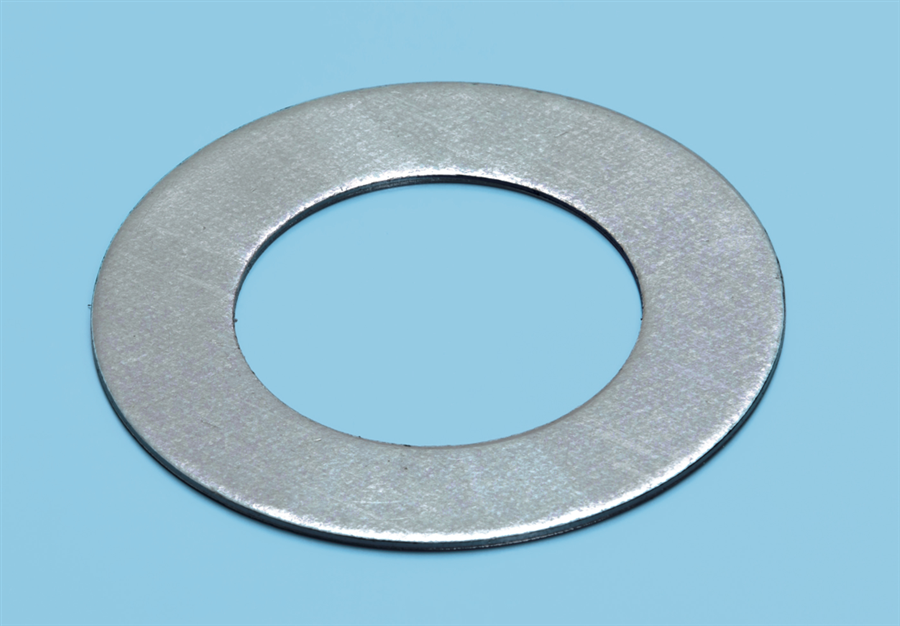

Expanded graphite gasket

GRASEAL™ GASKET PM-A

TOMBO™ No. 1215-A

It has excellent workability and can be machined into complex shapes.

It is used for uniquely shaped flanges, valve bonnets, heat exchangers, etc.

Spiral wound gaskets with expanded graphite filler (for low temperatures and low surface pressure sealant)

VORTEX™ GASKET

TOMBO™ No. 1839R

It is a gasket with a large amount of filler outside the sealed surface and that enables a seal with less clamping force than regular GRASEAL™ and VORTEX™ gaskets.

It can also be used for low-temperature production lines such as liquefied natural gas (LNG), liquid nitrogen (LN2), and liquefied air.

Spiral wound gasket with expanded graphite filler

VORTEX™ GASKET

TOMBO™ No. 1804-GR

It demonstrates excellent sealing performance even in strict conditions such as high temperatures and high pressures, ultra-low temperatures, and thermal cycles.

It offers better sealing performance than NA VORTEX GASKET (particularly sealing against gas).

As it has excellent corrosion resistance, it can be used for corrosive fluids if you choose an appropriate hoop material.

It has excellent sealing performance at low-temperature conditions.

It is a gasket that is particularly suitable for high-temperature and high-pressure steam applications such as pipe flanges, valves, pressure containers, heat exchangers, and valve bonnets of various industries, as well as low-temperature applications like liquefied natural gas (LNG).

Spiral wound gaskets with expanded graphite filler (for low temperatures and low surface pressure sealant)

VORTEX™ GASKET

TOMBO™ No. 1839R

It is a gasket with a large amount of filler outside the sealed surface and that enables a seal with less clamping force than regular GRASEAL™ and VORTEX™ gaskets.

It can also be used for low-temperature production lines such as liquefied natural gas (LNG), liquid nitrogen (LN2), and liquefied air.

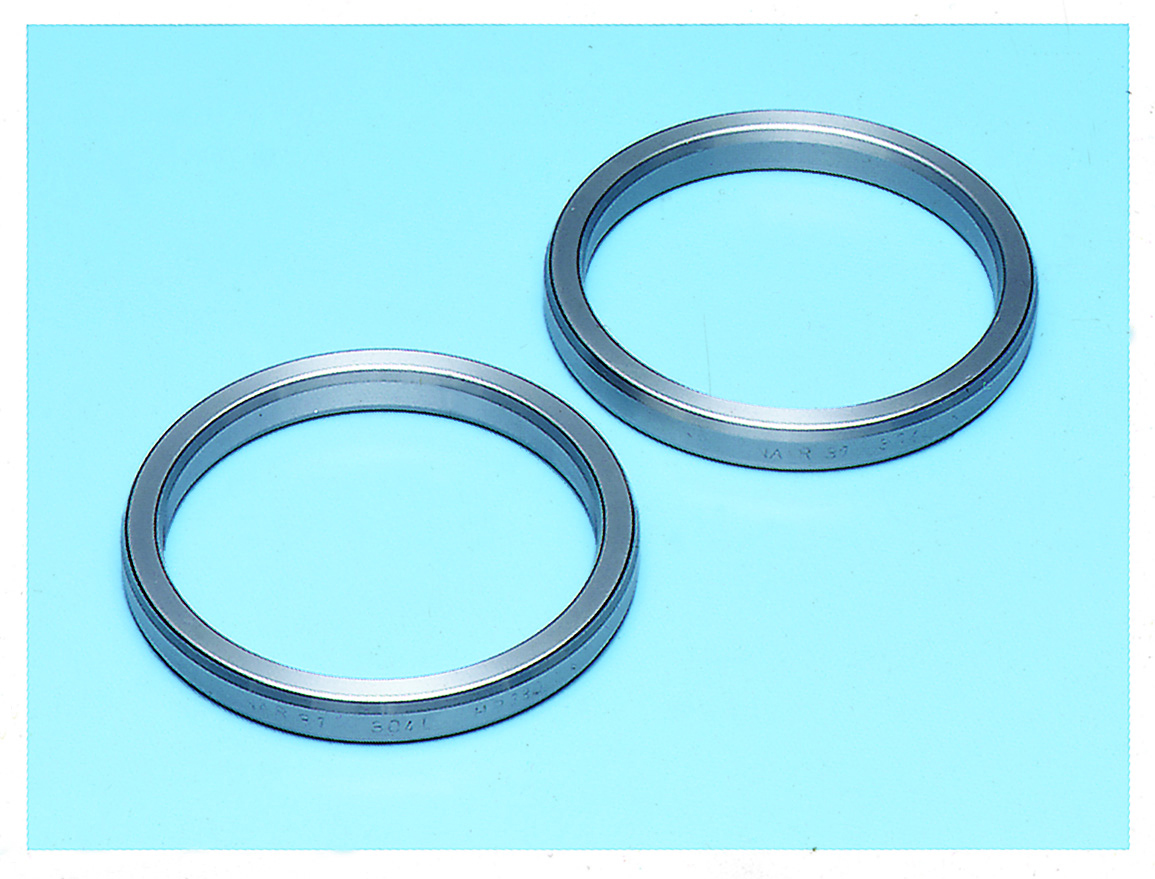

other packing

OCT RING JOINT GASKET

TOMBO™ No. 1850C

The Ring Joint Gasket is a gasket processed into specific shapes by machining cast metal materials. It is used for high-temperature, high-pressure pipe flanges, valves, pressure containers, and heat exchangers.

OCT RING JOINT GASKET is a gasket that offers sealing properties by having the sealed surface and the flange grooves engage in surface-to-surface contact. If carrying out sliding work, the gasket can be reused (providing the sealed surface is in good condition).

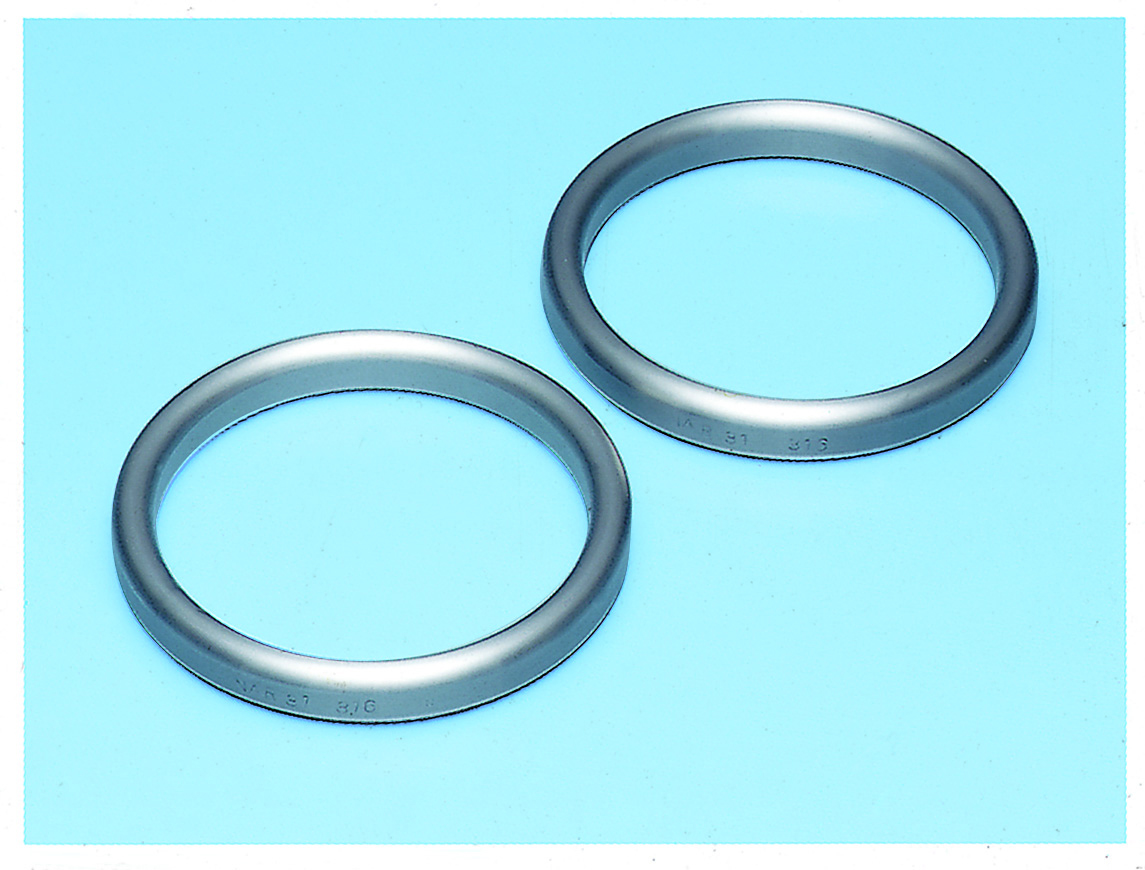

OVAL RING JOINT GASKET

OVAL RING JOINT GASKET

TOMBO™ No. 1850V

The Ring Joint Gasket is a gasket processed into specific shapes by machining cast metal materials. It is used for high-temperature, high-pressure pipe flanges, valves, pressure containers, and heat exchangers.

With its oval shape, the sealed surface forms a linear contact and so it adapts easily to the flange grooves. On the other hand, the ring cannot be reused.

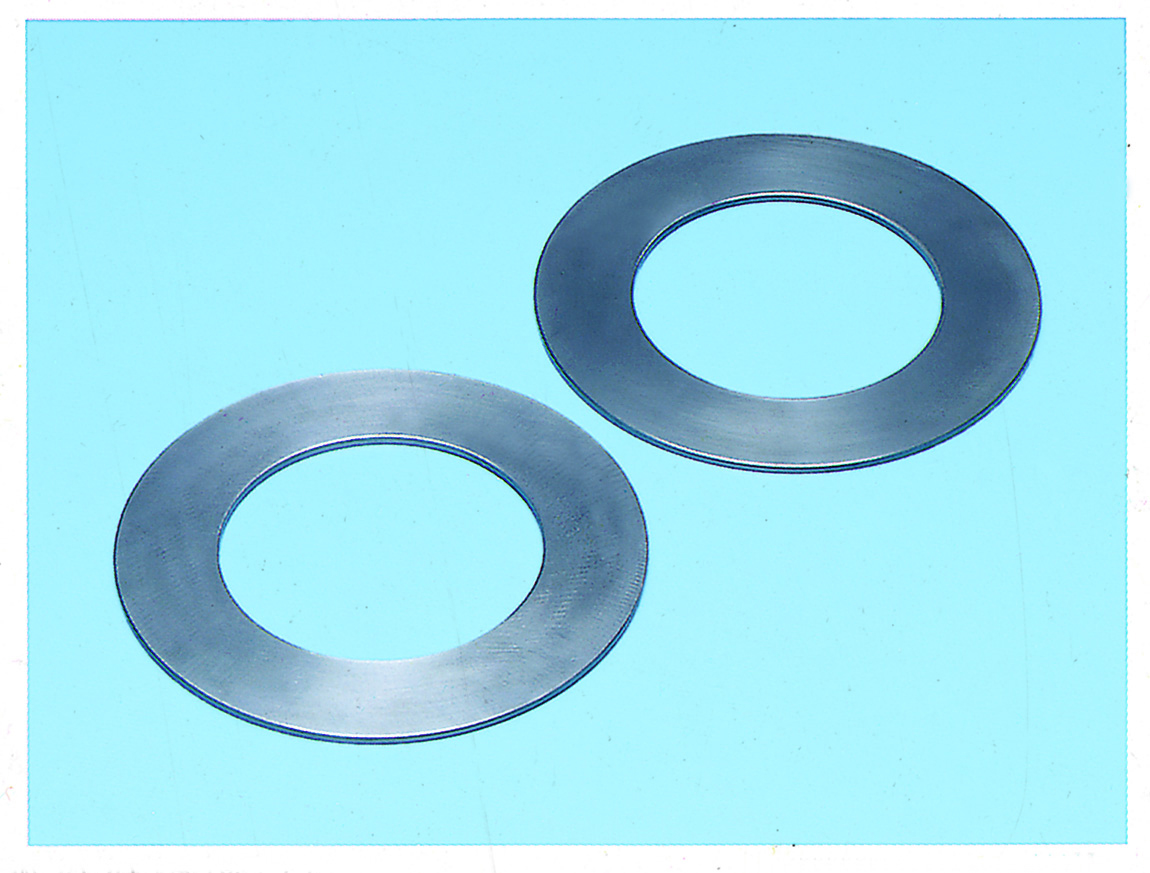

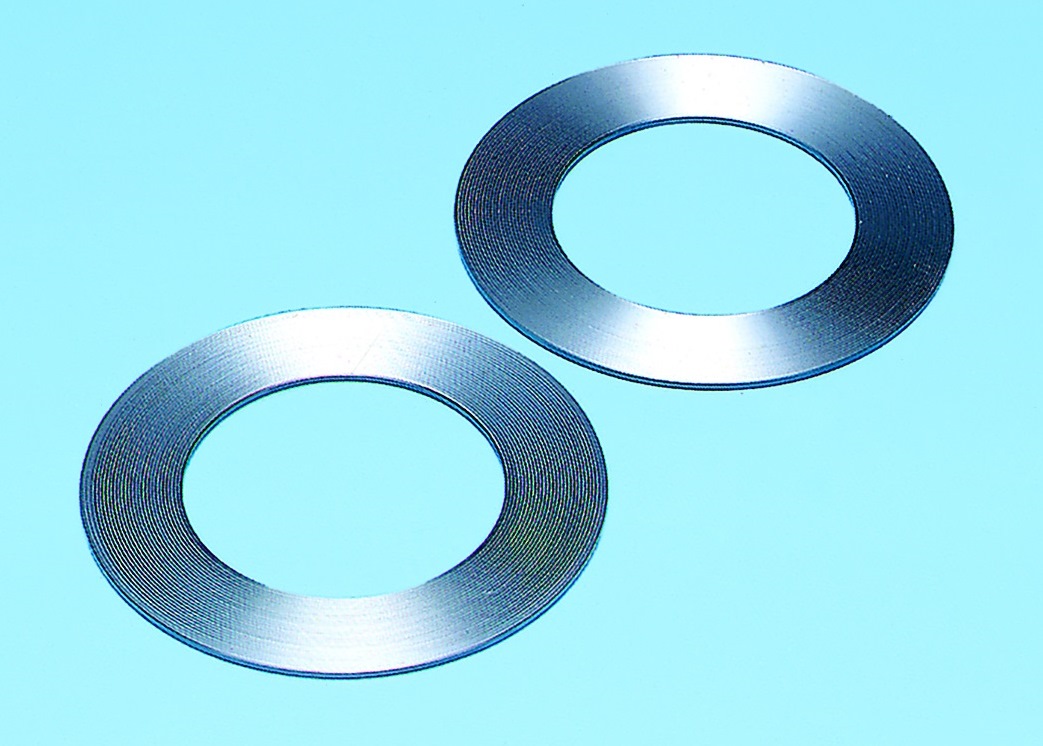

FLAT METALLIC GASKET

FLAT METALLIC GASKET

TOMBO™ No. 1850P

A flat gasket that is made by flattening metal.

The sealed surface adapts to the flange, and so a high clamping pressure is required.

To improve the sealing properties, nubbins may be machined on the flange.

Metal solid gasket (serrated)

SERRATED METALLIC GASKET

TOMBO™ No. 1890

Its shape gives it excellent sealing properties compared to flat metal gaskets.

Although it is subject to concentrated surface pressure, the flange surface may get scratched.

It is a gasket used for pipe flanges, valves, pressure containers, and heat exchangers.

Hollow metal ring

METAL O-SEAL

TOMBO™ No. 9200P

A gasket made by molding thin metal piping into the shape of an O-ring, welding it at the ends, and then subjecting the surface to ultra-precision finishing. This gasket provides a very reliable, top-class seal across a wide range of conditions from high temperatures to low temperatures and high pressure to vacuum states.

It is used by fitting it onto the grooves and fully clamping it to enable a high-pressure seal with little clamping force.

If the internal pressure is 7 MPa or more, please use TOMBO No.9200V (model with holes).

In the case of gaseous fluids, vacuumed fluids, and highly volatile fluids, Nichias recommends its PTFE coating or silver plating specifications.

It is used for various applications such as valve bonnets, high-pressure container flanges, equipment joints, pipe flanges, plastic processing machinery, rubber extruders, hydraulic equipment, air pressure equipment, vacuum equipment, nuclear vessels, aircraft engines, rocket engines, and automobile engines.